Abrasive Wheels Course

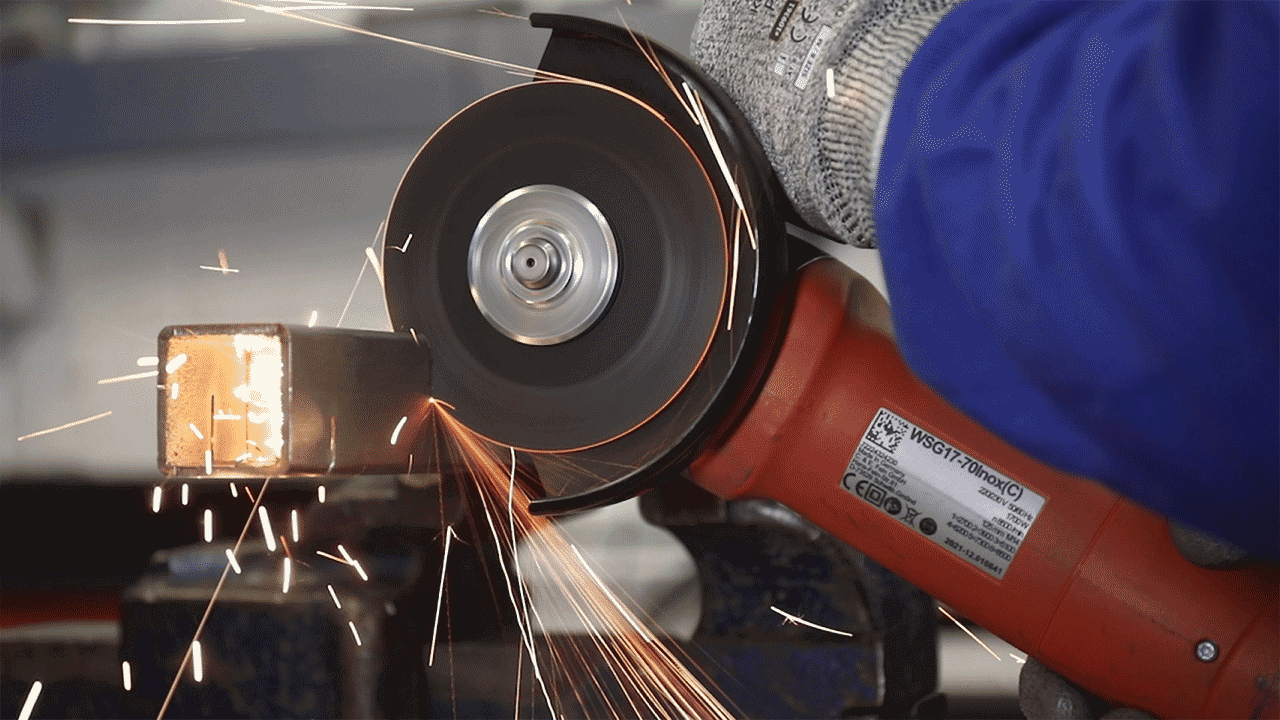

Abrasive Wheels Course - All products are recognized by the highest safety and manufacturing standards. Coated abrasives, surface conditioning, resin bonded, precision vitrified. How long will the course take? List the methods of storage, handling and transportation of abrasive wheels; Demonstrate the correct method of mounting an abrasive wheel including knowledge of the function of the components The abrasive wheels online course is an elearning course designed for workers who handle, operate, and maintain abrasive wheels in the workplace. The abrasive wheels course is suitable for anyone who fits abrasive wheels to work equipment or uses work equipment fitted with abrasive wheels should take this course to comply with the. The abrasive wheels safety training course has been designed to give workers, supervisors, managers and safety professionals a thorough grounding in safe practices, legal obligations and practical measures that reduce the likelihood of accidents. The course covers the most current legislation and regulations which apply to abrasive wheels. Identify the methods of marking abrasive wheels as to type and speed; Special alloy molds are used for dimensional uniformity and performance consistency. It also shows you how to inspect different abrasive wheel types. We make abrasive products to spec from top grade materials. Gain essential skills to ensure workplace safety & compliance. Plants and (3) plants in israel, all totaling over 400,000 square feet of manufacturing space. How long will the course take? The abrasive wheels online course is an elearning course designed for workers who handle, operate, and maintain abrasive wheels in the workplace. Identify different types of abrasive wheels and their applications. Choose blastone for extended equipment life and a superior blasting experience. Successful candidates will receive a citb 'approved' training certificate and photo id card. Successful candidates will receive a citb 'approved' training certificate and photo id card. Participants will also learn about legislation, storage, handling, and inspection. You will learn about relevant legislation and how to safely use and inspect different abrasive wheel types, amongst other topics. Who is the abrasive wheels course suitable for? The abrasive wheels safety training course has been designed. Special alloy molds are used for dimensional uniformity and performance consistency. We make abrasive products to spec from top grade materials. Identify the methods of marking abrasive wheels as to type and speed; Blastone’s cleaner abrasives enhance efficiency and visibility, while our training keeps operators happy and productive. Who is the abrasive wheels course suitable for? You will learn about relevant legislation and how to safely use and inspect different abrasive wheel types, amongst other topics. Learn how to safely operate abrasive wheels with our comprehensive abrasive wheels training. Participants will also learn about legislation, storage, handling, and inspection. This course is designed to provide the necessary knowledge and skills required to demonstrate the selection and. This course covers the types, uses, hazards, and necessary control measures to reduce injury risks when using abrasive wheels. Coated abrasives, surface conditioning, resin bonded, precision vitrified. How long will the course take? It also shows you how to inspect different abrasive wheel types. Learn about wheel types, safe operations, and inspection techniques to ensure workplace safety and compliance. Blastone’s cleaner abrasives enhance efficiency and visibility, while our training keeps operators happy and productive. Perfect for professionals in manufacturing, engineering, and construction sectors. Learn how to safely operate abrasive wheels with our comprehensive abrasive wheels training. Plants and (3) plants in israel, all totaling over 400,000 square feet of manufacturing space. It also shows you how to inspect different. Learn about wheel types, safe operations, and inspection techniques to ensure workplace safety and compliance. Identify hazards which could affect the machine operator when using abrasive grinding wheels for precision grinding processes. Demonstrate the correct method of mounting an abrasive wheel including knowledge of the function of the components Wheels are precision fired in microprocessor controlled kilns capable of duplicating. Wheels are precision fired in microprocessor controlled kilns capable of duplicating critical firing temperature profiles. We make abrasive products to spec from top grade materials. Successful candidates will receive a citb 'approved' training certificate and photo id card. Participants will also learn about legislation, storage, handling, and inspection. Firstly, this course is designed for anyone that uses abrasive wheels in. We make abrasive products to spec from top grade materials. Understand the legal requirements for safe use and handling of abrasive wheels. You will learn about relevant legislation and how to safely use and inspect different abrasive wheel types, amongst other topics. The abrasive wheels course is suitable for anyone who fits abrasive wheels to work equipment or uses work. Identify different types of abrasive wheels and their applications. The course covers the most current legislation and regulations which apply to abrasive wheels. Identify the methods of marking abrasive wheels as to type and speed; Plants and (3) plants in israel, all totaling over 400,000 square feet of manufacturing space. Stay safe and compliant with our abrasive wheels awareness course. This course is designed to provide the necessary knowledge and skills required to demonstrate the selection and safe fitting of abrasive wheels in accordance with manufacturer’s guidance and current legislation. This abrasive wheels online training course is designed to assist in reducing the risk of injury for anyone who uses abrasive wheels at work. Choose blastone for extended equipment life. This abrasive wheels online training course is designed to assist in reducing the risk of injury for anyone who uses abrasive wheels at work. Identify the methods of marking abrasive wheels as to type and speed; Participants will also learn about legislation, storage, handling, and inspection. Show the methods for testing and inspecting wheels for damage; Stay safe and compliant with our abrasive wheels awareness course. The abrasive wheels online course is an elearning course designed for workers who handle, operate, and maintain abrasive wheels in the workplace. Choose blastone for extended equipment life and a superior blasting experience. Demonstrate the correct method of mounting an abrasive wheel including knowledge of the function of the components Blastone’s cleaner abrasives enhance efficiency and visibility, while our training keeps operators happy and productive. Learn how to safely operate abrasive wheels with our comprehensive abrasive wheels training. It also shows you how to inspect different abrasive wheel types. Designed to give you the essential knowledge and confidence to handle abrasive wheels safely, this training ensures you’re fully informed and up to date with current health and safety regulations. Wheels are precision fired in microprocessor controlled kilns capable of duplicating critical firing temperature profiles. Identify hazards which could affect the machine operator when using abrasive grinding wheels for precision grinding processes. Master abrasive wheel safety with our expert training course. We make abrasive products to spec from top grade materials.Abrasive Wheels Training Course

Abrasive Wheels Training Course

Abrasive Wheels Course Notes First Aid Supplies

Global Abrasive Wheels Course 2022 Learn with the Master! … Flickr

Abrasive Wheels Course Online £12 50mins Certificate

Abrasive Wheels • Smiths Training

Abrasive Wheel Safety Training We Do ELearning

Abrasive Wheels Training Course Online John Academy

Online Abrasive Wheels Course, CPD Certified, IIRSM Approved Training

Abrasive Wheels Training Course Carl Wright Training Services

Identify Different Types Of Abrasive Wheels And Their Applications.

Plants And (3) Plants In Israel, All Totaling Over 400,000 Square Feet Of Manufacturing Space.

The Course Covers The Most Current Legislation And Regulations Which Apply To Abrasive Wheels.

Our Team Understands The Key Variables That Make Or Break Production — Material Type, Machining Speeds, Tolerances, And Tool Longevity — And We Design With Every One Of Those In Mind.

Related Post: